Servo Motor Manufacturer

Snabify specializes in the design, production, and distribution of highly precise and robust servo motors that cater to a broad range of industrial and commercial applications.

What Is A Servo Motor?

A servo motor is a rotary actuator or linear actuator that allows for precise control of angular or linear position, velocity, and acceleration. It typically consists of a motor coupled to a sensor for position feedback, along with a sophisticated controller, often packaged within the motor housing.

Servo motors are distinct for their feedback loop which enables precise control. The controller will continuously adjust the motor’s direction and speed until the current position matches the target position.

Explore Top-Quality, High-Efficiency Servo Motors

DC Servo Motor

Brushless Servo Motor

Industrial Servo Motor

Bldc Motor With Encoder

Bldc Motor With Gearbox

Your Reliable BLDC Motor Manufacturer In China

Our BLDC motors are built to last in a wide range of applications

Our employees are able to react quickly

Over 9 years of experience in BLDC manufacturing.

Snabify's BLDC motor can meet your requirements.

Snabify offers BLDC motors with different specifications, if you are looking for them, please contact us to get their prices.

Manufacturing Process

As an emerging field in modern motors, the production process of brushless motor is a very complex process. Copper wire production, coil winding, rotor molding, component assembly and other process links need to go through repeated and meticulous processing.

As long as the process is strictly followed in each link, the high-quality brushless motor that meets the requirements can be produced.

1. Copper Wire Production.

2. Coil winding.

3. Rotor forming.

4. Component assembly.

Advantages Of BLDC Motor In Snabify

Factory Price

Snabify offers cost effective bldc motor. We ensure our customers enjoy unbeatable value, cutting out middlemen to provide high-quality products directly from our workshop to you.

High Durability

Our products are engineered for high durability, ensuring they withstand the test of time and deliver consistent performance under the most demanding conditions.

High Durability

Our BLDC motors are engineered for high durability, ensuring they withstand the test of time and deliver consistent performance under the most demanding conditions.

Low Electrical Noise

Snabify BLDC motors are designed with low electrical noise, ensuring smooth operation and minimal interference, perfect for precision-sensitive applications.

Low Electrical Noise

Our motors are designed with low electrical noise, ensuring smooth operation and minimal interference, perfect for precision-sensitive applications.

Run Smoothly

Designed to run smoothly, our BLDC motors guarantee seamless performance, enhancing efficiency and reliability in every application they power.

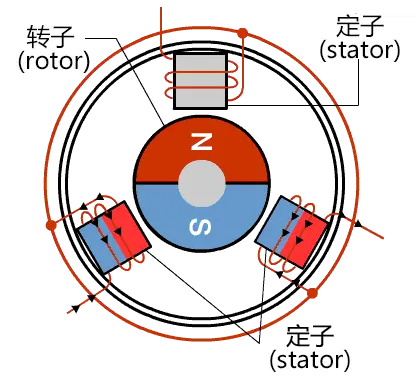

Construction of Brushless DC Motor

The brushless DC motor is composed of a motor body and a driver, which is a typical mechatronics product.

The stator winding of the motor is mostly made of three-phase symmetrical star connection, which is very similar to the three-phase asynchronous motor. A magnetized permanent magnet is glued to the rotor of the motor, and a position sensor is installed in the motor to detect the polarity of the rotor of the motor.

The driver is composed of power electronic devices and integrated circuits, and its functions are to accept all kinds of signals of the motor.

Bldc Motor Applications

Brushless DC motor (BLDC) has been widely used in many fields due to its high efficiency, low noise, and high-precision control. The following are its applications in different fields.

Industrial automation: CNC machining equipment, industrial sewing machines, light printing machinery, food processing machinery, industrial robots.

Medical field: Sleep apnea devices, dental drills, medical diagnostic CT machine.

Other fields: automatic doors, elevators, water pumps, packaging machinery, food machinery, printing machinery, material conveying machinery, textile machinery, etc.

Your Trustworthy Brushless DC Motor Supplier

Snabify is one of BLDC motor manufacturers in China, with excelent design engineers and experienced sales team.

As your trustworthy brushless DC motor supplier, we ensure every motor we supply meets the highest standards for your applications.

If you want to know the brushless dc motor price and specifications, contact us now.

Frequently Asked Questions

You can find some answers to frequently asked questions about brushless dc motors here. We hope they will be helpful to you.

For brushless dc motor, there is no limit on MOQ. Because our brushless dc motors are custom-made products and are used in different fields.

Usually 7-15 days. If it is necessary to redesign, open a new mold, the time is determined according to the specific situation.

Qualtiy is the key factor four our business. Ensuring the quality of BLDC motors involves several key steps:

Material Selection: Use high-quality materials for motor components to ensure durability and performance.

Design and Engineering: Employ experienced engineers to design motors with efficiency, reliability, and application-specific requirements in mind.

Precision Manufacturing: Utilize advanced manufacturing techniques and machinery to maintain tight tolerances and high-quality standards during production.

Rigorous Testing: Implement comprehensive testing protocols, including performance, durability, and safety tests, to ensure each motor meets strict quality criteria.

Quality Control: Conduct thorough inspections at various stages of production to detect and rectify any defects.

Feedback Integration: Analyze customer feedback and field performance data to continuously improve product quality.

At first you can send an inquiry, tell us your different requirements such as brushless motor applications fields, rated voltage, speed, motor torque, output power and so on. After get your details, we will send you bldc motor specifications with price.

BLDC (Brushless DC) motors are favored for numerous applications due to their distinctive advantages:

- Enhanced Efficiency: Without brushes, BLDC motors minimize friction and energy loss, surpassing traditional brushed DC motors in efficiency.

- Superior Power Density: Their high power-to-size ratio makes them perfect for space-constrained applications.

- Extended Durability: The brushless design significantly reduces wear, extending the motor’s lifespan and reducing maintenance needs.

- Accurate Speed Control: They provide precise speed regulation and high torque across a broad speed range, essential for applications requiring exact control.

- Reduced Noise and Vibration: BLDC motors operate more quietly and with less vibration than brushed DC motors, ideal for noise-sensitive environments.

- Minimal Electromagnetic Interference: Generating lower electromagnetic interference, BLDC motors are suitable for use near sensitive electronic equipment.

Given these benefits, BLDC motors are a preferred choice across various sectors, including robotics, electric vehicles, home appliances, and industrial equipment, offering a blend of efficiency, longevity, and performance.

A BLDC motor features electromagnets in the stator and permanent magnets on the rotor. The stator’s electromagnets receive power from a pulsed supply.

This motor operates on a 2-phase or 3-phase pulsed supply, characterized by rectangular or square waveforms, which is generated by an electronic controller. This controller transforms DC voltage, sourced either from a battery or rectifier, into a sequence of pulses directed to the motor’s stator.

With the pulsed supply, the stator’s electromagnets periodically switch polarity, creating a rotating magnetic field. This field interacts with the rotor’s permanent magnets, propelling the rotor through a series of magnetic “pushes” and “pulls.” This interaction generates torque and causes the rotor to turn. Adjusting the voltage of the pulsed supply allows for control over the motor’s speed.

Send Your Inquiry Today

Send us a message if you have any questions or request a quote. You will get reply within 2 hours.